EMC coating

EMC attenuation of plastic enclosures

We offer the following procedures:

Attenuation by means of painting

Coating with EMC conductive lacquer, an electrically conductive layer of copper, nickel, graphite or copper, metallised by silver, is applied to the enclosure parts.

In both procedures the surfaces, which should not and must not be coated, are covered with adhesive tape or masks. Preferably an UL-listed EMC conducting, copper-based lacquer, which has very good damping properties and ensures a highly electromagnetic absorption across a wide frequancy range, is used.

| Sheet resistance | 0,1 - 0,3 Ohm | |||

| Damping | 30 MHz 87 dB | 100 MHz 88 dB | 300 MHz 84 dB | 1000 MHz 36 dB |

| Dynamic range | 117 dB | 120 dB | 120 dB | 120 dB |

| Operating temperature | -40° C to +60° C | |||

| Storage temperature | up to 80° C ( depending on the thermal stability of the plastic) | |||

Testing was conducted according to the temporarily ASTM ESF-83 (CLOSED BOX METHOD) and was performed by an independent testing laboratory. The statements we make are all given according to the best of our knowledge, but do not release the customer to check the project-related suitability for the intended area of application. We reserve the right for technical modifications without prior notice at any time. We reject any and all liability combined with technical advice. Further details are regulated in our AGBs, to which we're expressly referring at this point. |

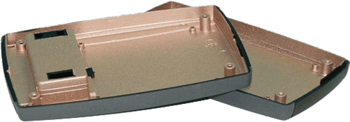

Additional protection through conductive gaskets

By using conductive gaskets another improvement of the shield-damping can be achieved.

Shielding by vaporizing aluminum

The vaporizing of aluminum occurs in high-vacuum systems and ensures for nearly all plastic materials an equally good

adhesion and long-term stability. We offer this procedure in cooperation with external partners.

If you have any questions - contact us!

WÖHR sectors in one click